Following the completion of a £4 million second phase, the Coal Authority’s Lynemouth mine water treatment scheme in Northumberland can now treat the equivalent of 2,400 Olympic-sized swimming pools of water every year – removing more than 300 tonnes of iron in the process.

The extended scheme is protecting millions of litres of drinkable water in the north east.

Carl Banton, operations director at the Coal Authority, commented on the announcement: “Our scheme will ensure rising water in the historical underground coal workings is effectively managed, protecting around 1.6 million cubic metres of groundwater and preventing uncontrolled discharges into rivers and the sea.”

Built on the site of the former Lynemouth colliery, the treatment scheme is one of the Coal Authority’s largest, pumping and treating iron-rich mine water before it is discharged into the North Sea.

Coal Authority project manager Jim Bagnall added: “The scheme was always intended to be completed in phases and the first two treatment lagoons were built in 2015.

“This slowed the rise of the mine water, allowing us to determine what long-term capacity was needed and the 5 new lagoons became operational at the beginning of this year.

“Lynemouth Colliery was part of a larger mining block linked to Ellington Colliery, known as Ellington Combine, which worked reserves under the North Sea.

“The mining block extends from Morpeth in the west to West Chevington in the north.

“Historically, mine water levels were controlled at a number of pumping stations in the area.

“However, pumping stopped in 1994, with Ellington colliery finally closing in 2005.”

Once the pumps that keep a mine dry are switched off, the water levels recover and naturally occurring minerals are picked up from the rocks, such as iron, and these affect the water quality.

At Lynemouth, groundwater lies above the coal measures and if the mine water rises unchecked it could cause irreversible pollution to this good quality water source.

There is also a longer term risk, if the mine water is allowed to rise above sea level, of potential uncontrolled discharges into rivers or the sea.

Although not harmful to people, the elevated levels of iron in the water could have a detrimental impact on local habitats and wildlife.

To treat the mine water, it is pumped to the top of cascades and flows down steps, which mixes in air to encourage dissolved iron to become solid.

The water then flows through a series of lagoons, where the iron accumulates at the bottom as ochre.

To maintain the performance of the scheme, this ochre is periodically transferred to one of two sludge-drying beds.

They are looking at opportunities to beneficially use the ochre waste produced at the site.

(Image by Coal Authority)

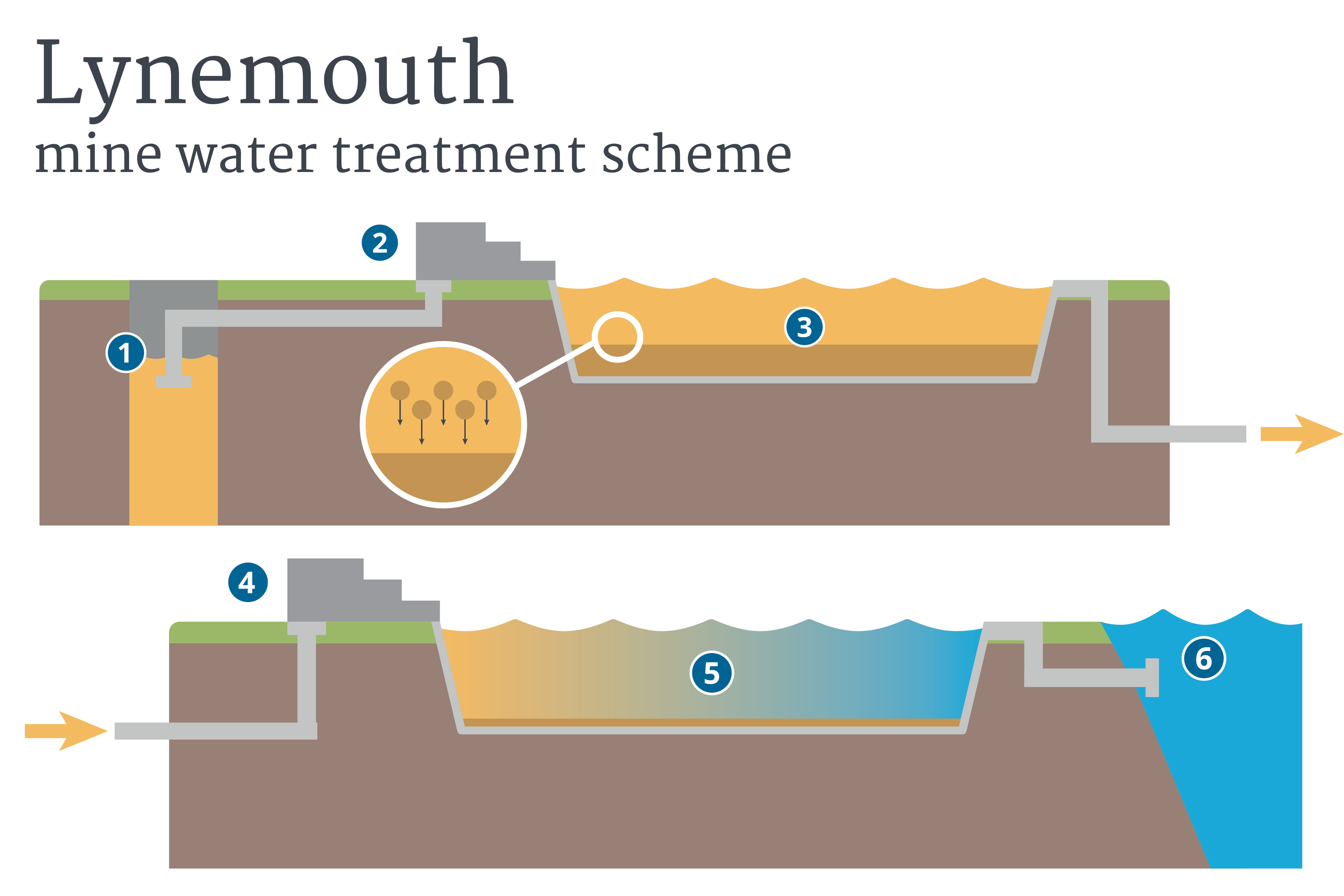

How it works:

- Water is pumped from the colliery’s old mine shaft to the top of a cascade.

- Air mixes with the mine water as it falls down the cascade steps, which causes the iron to oxidise and form particles.

- The water moves slowly through the lagoons, where large iron oxide particles fall out of solution and settle at the bottom as ochre.

- Air is added again by passing water over a second cascade to repeat the process and remove even more iron solids.

- To maintain the performance of the scheme, this ochre is periodically transferred to one of two sludge-drying beds and then a polytunnel, where excess water is removed to significantly reduce its volume, making it is easier to store or move.

- Water is discharged into the sea.